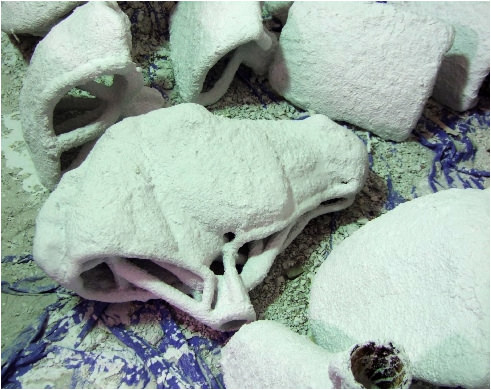

A mold is made in sections out of plaster

and rubber.

and rubber.

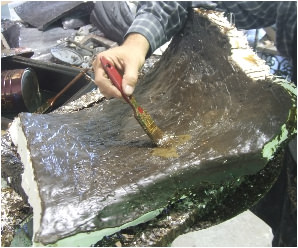

Wax is brushed in each of the sections until

the desired thickness is obtained. The wax

will be replaced by bronze so the thickness

of the wax will be the thickness of the

bronze.

the desired thickness is obtained. The wax

will be replaced by bronze so the thickness

of the wax will be the thickness of the

bronze.

Sections of the mold coated with wax.

Wax bars called “sprues” are attached to

determine where bronze will flow. A

Styrofoam cup acts as a form for a funnel

for the molten bronze.

determine where bronze will flow. A

Styrofoam cup acts as a form for a funnel

for the molten bronze.

The wax section with the sprues and cup attached is dipped into a

ceramic slurry, a mixture of silica powder and a colloidal silica binder.

ceramic slurry, a mixture of silica powder and a colloidal silica binder.

Then it is sprinkled with sand.

This is repeated until the desired thickness is obtained. In this case, 10

coats, which is about 1/2" thick.

coats, which is about 1/2" thick.